Embroidery vs print – which is better for branded workwear?

Which is better for branded workwear, embroidery or print? Andrew Grinnell, Director at iSB Group looks at the advantages and disadvantages of both options for garment branding…

We are often asked by clients which is the better option for applying their company branding to workwear – embroidery or print. The simple answer is that neither is better than the other – they both come with advantages and disadvantages that mean they suit some requirements better than others.

Embroidery is more hard-wearing, but can be pricier at the outset and not ideal for waterproof garments or logos with complex graphics.

Printed transfers applied with a heat pad may be cheaper and offer quicker turnaround times, but can stretch and peel with time.

Let’s find out more…

Branded workwear – a popular choice

From custom polo shirts and soft-shell jackets for customer-facing employees, to eye-catching waterproofs for delivery drivers, and comfortable, warm high-vis for warehouse workers and production line operatives, branded workwear is becoming more and more popular.

Advances in application processes and materials mean more types of fabrics and designs of garments can now be branded than ever before, offering businesses a wide range of options to suit their individual employees and the demands of their roles.

This choice extends, too, to how the branding is applied, with both printed transfers and embroidery available as options for employers to consider.

There are advantages and disadvantages of both methods of branding. These are:

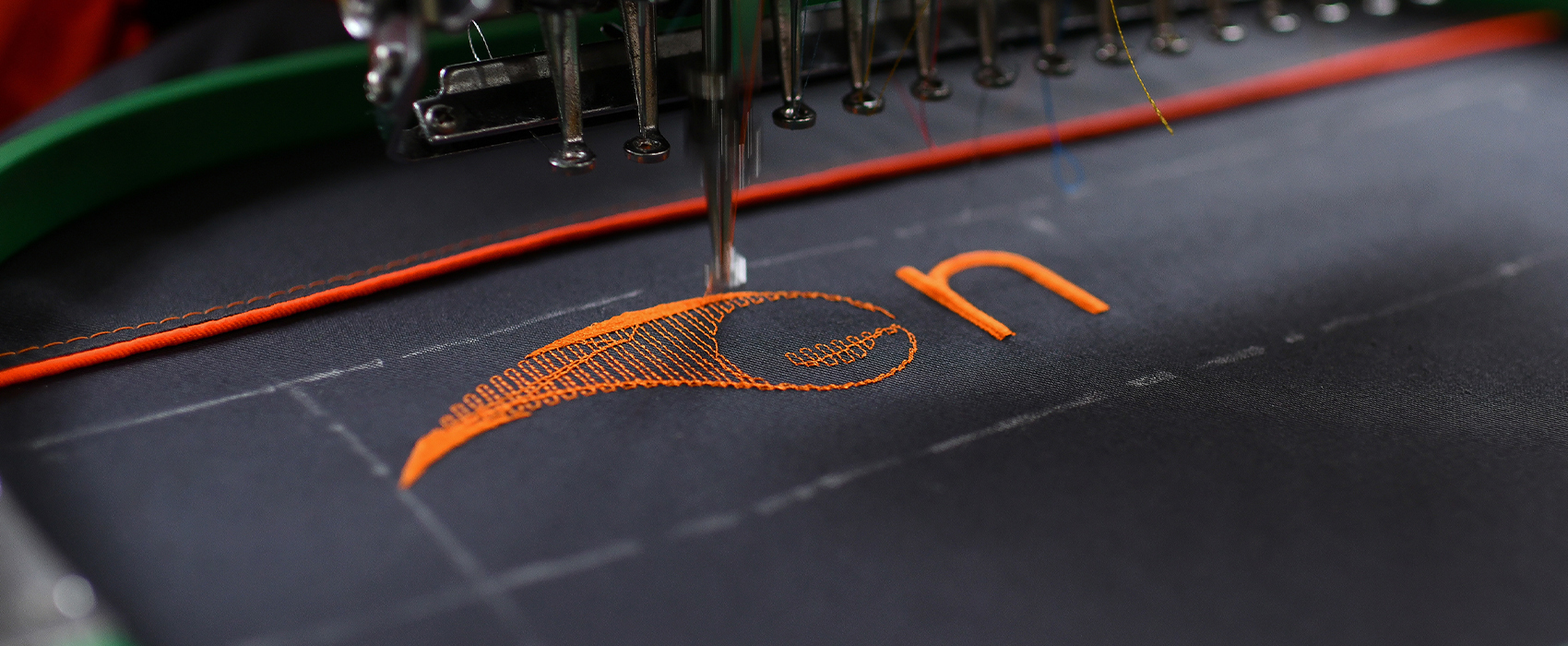

Embroidery: the pros

- Extremely hard-wearing – will last as long as the garment, without the colours fading,

- Ideal for bulk rollouts,

- Can be used on stretchy fabrics without fear of the design distorting over time,

- May be made with flame retardant thread.

Embroidery: the cons

- Logo designs with complex shading and graphics will need to be simplified,

- May not be suitable for waterproof items due to introducing holes into the garment,

- Can be an expensive option for one-off or small production runs, or where multiple logos are required due to set up costs,

- Turnaround times for subsequent orders may be longer if items are not held in stock.

Printed transfers: the pros

- Capable of producing an exact replica of even the most complex graphics and logos,

- May be applied to waterproof items without damaging their protective properties,

- A cheaper option for one-off and small production runs as well as multiple logos, due to lower set-up costs,

- Flame retardant transfers are an option, and may be cheaper than the equivalent embroidery,

- Offers the quickest turnaround time for repeat orders where items are not held in stock.

Printed transfers: the cons

- Prone to peeling over time and with multiple washes,

- Solid block transfers on stretchy garments will crack and distort over time,

- Sometimes perceived as less smart than embroidery.

Embroidery vs print – which is better?

Choosing the best method of branding your company workwear requires understanding how that workwear will be used in practice – who will wear it, in what environment, and what the physical demands are of their role.

In some cases, there may be a clear ‘better’ option, and a good workwear supplier will be able to advise you on what that may be.

Sometimes, it may just come down to personal choice of which you prefer and which you feel best suits your company brand.

You might also like

Best Embroidered Polo Shirts 2025