Standards for cut-protection safety gloves in Europe were expanded in 2016 to offer greater insight into product performance by hazard type. The existing standard, EN 388:2003, graded safety gloves according to their resistance to constant pressure from a blade. The updated standard, EN 388:2016 / ISO 13997 also takes into account resistance to single, sudden impacts with a sharp object.

How does this affect the logistics industry, and what do employers need to know about the updated standards? Clive Grinnell explains…

Cut-protection safety standards up to 2016

Prior to 2016, cut protection safety gloves were regulated in Europe by the standard EN 388:2003, which rated the performance level of products from 1 to 5, with 5 being the highest.

Testing to this standard involved passing a rotating circular knife back and forth across the glove with constant pressure until it cut through. The sharpness of the blade was measured at the beginning and end of the test, and the degree of wear and tear combined with the cycle count required to cut through the test product gave the product its performance rating.

Current cut-protection safety standards

In 2016, EN 388 was expanded to incorporate ISO 13997. Under this regulation, cut-protection safety gloves made from certain materials are required to be subject to a further test that identifies their resistance to single force impacts with sharp products.

A long, straight blade is passed over the test product once, and the level of force required to cut the material measured. The gloves are then assigned a cut protection class from A to F based on this measurement.

Why was the standard expanded?

It is normal for standards and testing methods for safety products to change along with advances in the materials used to manufacture them.

EN 388 was expanded to offer more detailed information about cut-protection in gloves incorporating high performance glass and steel fibres. Designed to have a blunting effect on a blade, the presence of these fibres in glove fabrics enables products to achieve higher ratings under the constant pressure test, but this doesn’t tell the wearer or purchaser how that glove will stand up to sudden impacts with sharp objects.

By combining the two standards, employers now have much greater information at their disposal about the performance level of cut-protection safety gloves, and can determine the best option for specific applications based on duration and type of cutting force.

Cut-protection safety standards: what do employers need to know?

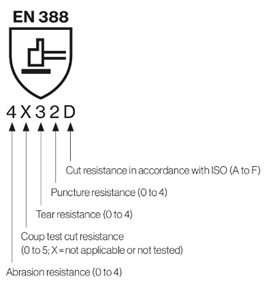

Cut-protection safety gloves tested to both standards will now display something that looks like this:

The combination of numbers and letters used to make up ratings under EN 388:2016 / ISO 13997 offers much greater information about a glove’s resistance to different sharp object hazards, allowing employers to make more informed decisions about the best products to purchase for specific applications in the workplace.

Scoring highly under the numbers-based standard means a safety glove performs well against contact with sharp, relatively lightweight objects. Meanwhile, the letter-based score indicates the level of performance when working with heavier objects with greater force, and against impact-based dangers. Performing well in one test method does not necessarily mean a glove will perform equally well under the other.

What do I need to take into account when buying safety gloves in future?

For employers, the numbers-based performance rating of their safety gloves will remain the same. The new testing standard is not yet mandatory, meaning that many of the safety gloves on the market are only tested to the numbers-based standard.

As combined testing becomes the norm, it will be important that employers revisit their safety glove provision to ensure it is providing the optimum protection for the specific hazards present in their workplace.

A good PPE supplier will be able to help you conduct this risk assessment, as well as answer any questions you may have about cut-protection safety standards and the timeline their manufacturers are working to in testing their products against the combined standard.

Find out more: Book a glove audit with the iSB team

You Might Like...

1

1

Gravity Jupiter Safety Trainers- E3200

Ultra resistant textile TECNO-TEXT upper

2

2

Gravity Jupiter Safety Trainers- E3200

Ultra resistant textile TECNO-TEXT upper

3

3

Gravity Jupiter Safety Trainers- E3200

Ultra resistant textile TECNO-TEXT upper

4

4

Gravity Jupiter Safety Trainers- E3200

Ultra resistant textile TECNO-TEXT upper